Firearms technology is ever-evolving. Companies who ignore the adage “innovate or die,” rarely remain relevant, if they survive at all. Suppressor companies, as a subset of the firearms industry, face the same challenge. As suppressors grow more popular, companies must stay on or near the

leading edge to compete. On a recent visit to SilencerCo, we saw what that company is doing not only to stay on the edge, but to drive it forward.

We spent time with SilencerCo Founder and CEO Jonathan Shults, Public Relations Specialist Shauna Young, and Marketing guys Caleb Gosnell and Cody Wootton. Along the way, we saw how SilencerCo is revamping its production facility and processes, looked at some new products, and did some live fire on the company’s indoor test range.

Changing For the Better

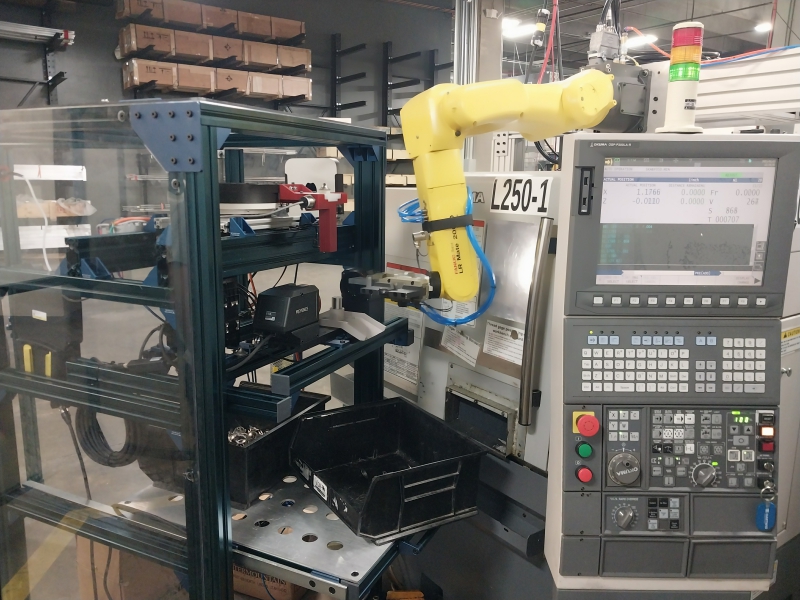

We were a bit surprised when Shults himself conducted the facility tour, but who better to brief us on everything that’s happening? Being an engineer, the focus quickly turned to SilencerCo’s investments in automation. Tedious jobs like sorting are being phased out. Robots now do that. But before you decry the employee losing his job, that’s not how it works. Not at SilencerCo, anyway.

SilencerCo Founder and CEO Jonathan Shults gave us a personal tour. (Author’s Photo)

The robots do replace the human doing mundane jobs, but that human is now trained to oversee the robot, making certain it’s performing as intended. Shults told us that “By introducing higher levels of automation…we are creating greater efficiency for our company and more enjoyable jobs for our employees.” Shults wants the automation to allow his people “to spend more time on creative and high-level tasks.”

Shults also noted that “Time is time. Time is not money.” When we asked what he meant by that, he responded that “You cannot put a price tag on time. It has so much more value than any amount someone can pay you. These new automations will give that valuable time back to our employees and our company, freeing up the space to focus on growth and innovation.”

The new robots relieve employees from mundane jobs and let them focus on higher tasks. (Author’s Photo)

Shults stressed that no one has lost their job to a machine, nor will they. We expect that such investments, coupled with the right motivation, greatly benefit employee morale. And we know that happy employees do superior work. Sounds like a winning formula.

New and Better Products

The new robots and machine tools have given the company the time and incentive to examine how and why top-quality machines perform well. Company engineers have begun building their own machine tools tailored for their products. In the process, they gain insights into how future products can and should be designed to maximize the machines’ capabilities, opening up new innovative avenues.

One of those new products is the Velos Low Back Pressure suppressor designed specifically for the 5.56 NATO and .223 Remington cartridges. Shults told us the Velos LBP is the most durable suppressor SilencerCo has ever built. When we pressed him on that claim, he enthusiastically told us about the new patented Hoplon Blast Baffle, which deflects debris and is specially designed to extend the suppressor’s life, even on short-barreled rifles and with fully automatic fire.

The new Velos LBP is designed for the 5.56 NATO and .223 Remington Cartridges. (SilencerCo Photo)

But that’s not the Velos’ only innovation. The 3D printed Inconel 625 core is fully welded to the 17-4 stainless steel front and rear modules using a unique manufacturing process that we aren’t qualified to describe. Suffice it to say that’s pretty awesome, as we found out when we shot it later that day. Plus, the V-Series Cerakote means the finish will hold up for a long time. But let’s take a look at the specs:

SilencerCo Velos Low Back Pressure Suppressor

– Length: 5.98 inches

– Weight: 15.2 ounces

– Decibels at the Muzzle: 137.1 dB

– Caliber: 5.56 NATO/.223 Remington

– Full Auto Rated

– No Barrel Length Restrictions

– 17-4 Stainless Steel with a 3D Printed Inconel Core

– Finish: V-Series Cerakote (Black)

– Compatible with SilencerCo Charlie Accessories

The Velos LBP suppressor ships with the brand-new Charlie Flash Hider Front Cap, Charlie ASR Mount, ASR Flash Hider in ½ x 28, spanner wrench, and Charlie Tool.

We were able to try out the Velos LBP on several platforms at the indoor range. It was a real pleasure to shoot. Being indoors, we used ear pro, but it was still noticeably quiet. It almost seems wimpy to say it tamed the recoil a bit, being 5.56, but it did. And the gas was reduced too, as one would expect from the name. When we coupled it with the SilencerCo Gas Defeating Charging Handle, there seemed to be no gas at all.

The FightLite Dual Feed was our favorite way to test the Velos LBP suppressor. (SilencerCo Photo)

The Velos was fun all around but, unsurprisingly, we enjoyed the FightLite Industries Dual Feed AR the most. Seriously, what’s not to like about that combo? That the range time was the highlight of the day should not shock anyone either. It was a good time. If you’re looking for a dedicated suppressor for your AR-15, you might want to give the Velos LBP a hard look.

The Dogs

We would be remiss if we didn’t mention the good boys and girls that we saw around the SilencerCo facility. Seriously. The company encourages their employees to bring their dogs to work. Talk about a morale booster. They weren’t on the range, for obvious reasons, but we saw them in the offices, hallways, and even the production floor, which isn’t particularly loud. It just made everything better. Shults said, enthusiastically, that “Our dogs are really part of our team!”

This good boy’s name is Blue. We met him in a SilencerCo hallway on the way to the production floor. (Author’s Photo)

Doing Everything at Home

By “at home,” we mean that SilencerCo sources almost all their materials from the United States and is “working toward having everything 100 percent sourced in America,” according to Shults. “We want our business to support Americans on all levels: through the products that we sell and through the methods these products are made.”

The company is also as vertically integrated as it can be, doing all the manufacturing work in-house, the only suppressor company to do so. Shults told us that was important to him because it brings jobs to the people of Utah while giving the company “the ability to control our products and thereby ensures that customers are receiving the very best that we can produce.”

Those attitudes aren’t just lip service. Both times we’ve visited SilencerCo we’ve noticed the huge American flag hanging prominently above the production floor. Monthly “all hands” meetings are held under the flags, with each meeting opening with the Pledge of Allegiance.” Good stuff.

This large American flag hangs prominently over the SilencerCo production floor. (Author’s Photo)

Quality Service

Shults also emphasized the importance of customer service. After all, a company that doesn’t support its products and its customers won’t stay around long. The SilencerCo warranty department is also in-house and Shults says they usually turn warranty work around in 48 hours. He takes his company’s warranty so seriously that he laughingly told us that SilencerCo would even “fix stupid once.” We liked that.

Of course, in a perfect world, warranties would be unnecessary and we’ve heard folks disparage companies who offer them by saying they shouldn’t have to do so. But that’s just unrealistic and such bombastic comments aren’t helpful. The fact that good companies support their products is encouraging.

Looking Ahead

Shults’ enthusiasm for SilencerCo’s direction is contagious. But it wasn’t just him. The other folks we interacted with had the same energy. The employees on the production floor were focused and quite friendly when we asked them questions. Now, you could say that was because the boss was right there with us, but we should note that the boss was on an easy first name basis with everyone too. That’s a good sign.

That SilencerCo’s efforts to improve the experience and skills of their workers is a good thing seems unarguable. Happy employees take pride in their work and everyone benefits, including the end user of SilencerCo products.

Automation allows SilencerCo’s employees time for creativity and attention to detail. (Author’s Photo)

A firearms instructor once told us to buy and use products from companies “who give a damn about their customers.” It looks like Shults is fostering that kind of environment at SilencerCo. The company started fifteen years ago in a garage. Now it’s an industry leader. They must be doing something right.

Sounds 2 good to be true, but i’am with you and trust American made. We need American made all over this country.